PRODUCTS

PlasmaANNEALER

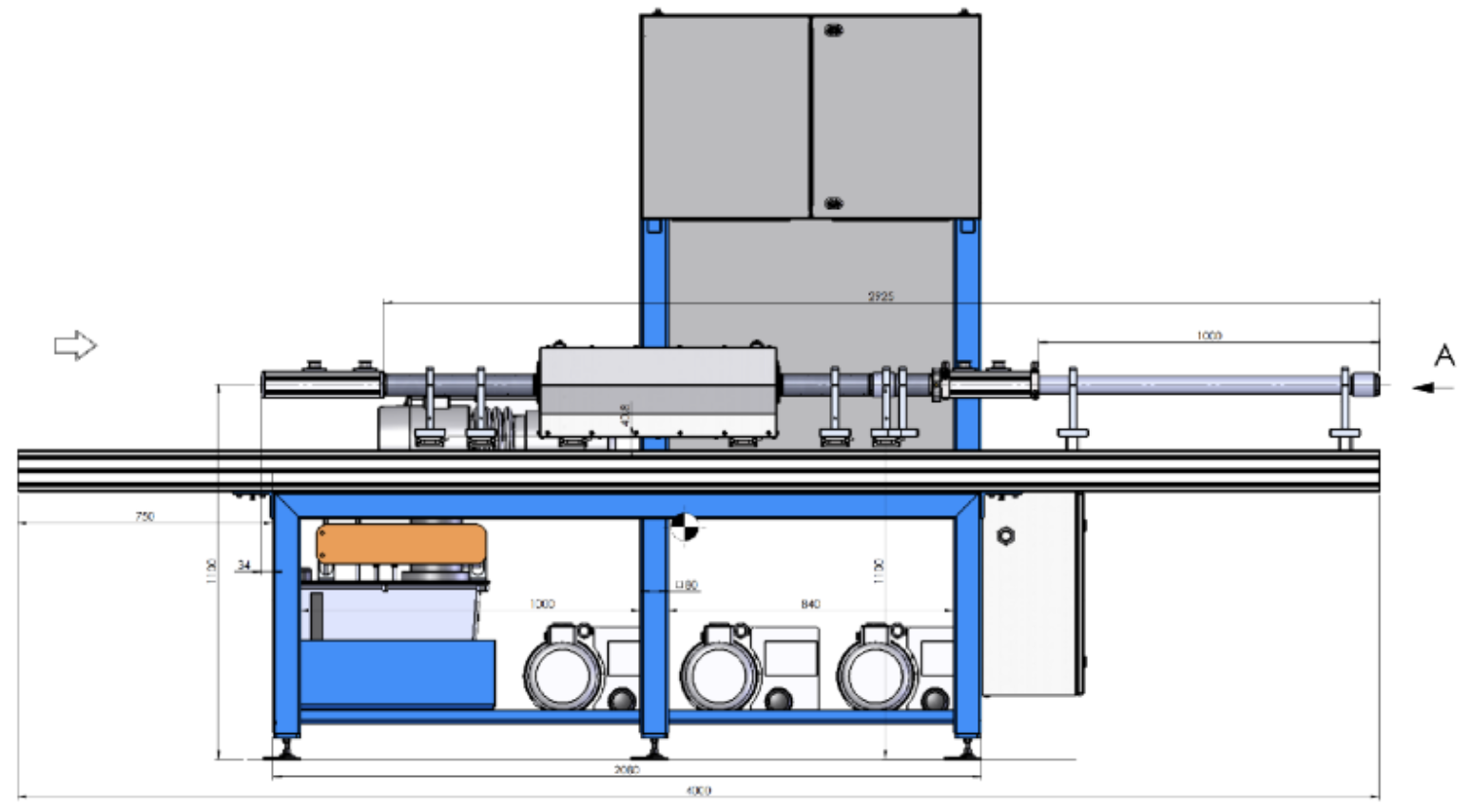

PlasmaANNEALER is a continuous heat treatment machine for ferrous and non-ferrous wire, rod, tube, rope and strip.

Why choose PlasmaANNEALER?

Branched utility

Plasma heat treatment can be used for annealing, stress relieving or hardening applications.

Materials

Copper and copper alloys

Stainless steel and steel alloys

Nickel, nickel alloys and nitinol

Titanium and titanium alloys

Aluminium and aluminium alloys

Molybdenum and tantalum

Gold, silver and other precious metals

Watch a video of PlasmaANNEALER

Benefits

Bright surfaced finish, scratch-free and without spark damage

Simultaneous degreasing and deoxidation in inert atmosphere

Adjustable mechanical properties

Fine and uniform grain size

Homogeneous grain in transversal and longitudinal direction

Less die wear in fewer wire breaks in subsequent drawing

High output annealing

Lowest production cost in class

Low energy, gas and maintenance costs

Small production footprint

Small power connection required

No warming-up/cooling-down time

Computer based controls with production and quality control features

What else?

Heat treatment: annealing, stress relieving, hardening

Material form: wire, rod, tube, strip, shaped wire, strand, rope

Process type: continuous

PlasmaPREPLATE

PlasmaPREPLATE process was designed for surface cleaning, surface oxide removal and annealing prior to plating for wires, strip or tube.

Why choose PlasmaPREPLATE?

PlasmaPREPLATE is a chemical-free alternative to chemical cleaning and fluxing. PlasmaPREPLATE can be installed in-line with electroplating or hot dip plating.

Materials

Copper and copper alloys

Steel alloys

Nickel, nickel alloys and nitinol

Aluminium and aluminium alloys

Watch a video of PlasmaPREPLATE

Benefits

Heat treatment - homogenous mechanical properties

Surface cleaning - removal of fine surface deposits

Degreasing - removal of wet lubricant for dry surface finish

Surface oxide removal - deoxidation under ion bombardment

Surface activation - surface preparation for better coating adhesion

Horizontal PlasmaPREPLATE for electroplating:

High-speed surface preparation

Simultaneous heat treatment

No acid pre-cleaning, no rinsing

Improved plating performance

Reduced cost of electroplating

Vertical PlasmaPREPLATE for hot-dip plating:

High plating speed

Acid-free surface preparation

Flux-free hot dip plating

Strong intermetallic layer

Low cost of operation

Integrated surface quality control

What else?

Material form: wire, rod, tube, strip, flat wire

Process type: Continuous

PlasmaSUPREX

PlasmaSUPREX is a plasma treatment machine designed for general surface preparation, preheating and annealing prior to any coating process including extrusion.

Why choose PlasmaSUPREX?

PlasmaSUPREX (SUrface PREparation for EXtrusion) offers the most cost effective and environmentally friendly technology, available on the market, with simpler production and higher end product quality.

This product family is a further development of PlasmaPREPLATE. It is a more specialized product for the extrusion market, launched in 2014 for plasma surface preparation before extrusion.

Materials

PEEK, PEAK, PTFE, PFS, PA, etc.

Benefits

Low processing / production costs

Drastic reduction in energy consumption

Nearly no water consumption

No chemicals required (no toxic waste or slag produced)

Higher flexibility on PEEK material options

More process steps in one machine

Better thermomechanical and thermoelectrical properties of the product

What else?

Material form: wire, rod, tube, strip, flat wire

Process type: Continuous

PV Ribbon Line

PV Ribbon Line is used for production of PV Ribbon. The production includes annealing and cleaning of copper ribbon prior to hot-dip tinning and spooling.

Why choose PV Ribbon Line?

This is an acid-free, flux-free, environmentally friendly process. It provides the operator with safe and clean working conditions. The production is fully automated utilizing an easy-to-use operator interface with integrated quality control features.

PV Ribbon Line components:

Payoff or integrated with rolling mill

Annealing and surface preparation

Tinning and wiping

Cooling

Takeup with accumulator

Operational benefits:

High production speed – up to 10m/min

Acid-free, flux-free and operator-friendly production

High production up time with utilization rate of up to 95%

Quick changeover between different product specifications

Short string-in time

Less scrap through better product control

Less tin waste due to flux-free production

Low power and gas consumption

Low maintenance costs

Computer process controls with user-friendly operator interface

Product quality benefits:

Smooth, consistent and shiny tin coat

Small tin coat thickness tolerance

Super-soft or extra-soft PV ribbon (Rp0.2% down to 50MPa)

Computer-based production know-how management

Computer-based quality control

Production recipe database

Integrated alarm system with fault record database

What else?

Process type: Continuous

Inlet Material: Rolled copper ribbon copper on 500kg spools

Size Range: Interconnect ribbon and bus bar

Finished Material: Tinned flat copper wire / PV ribbon on various spool sizes