About Plasmait

HISTORY

Plasmait was established in 2003 with the aim to design, build and supply plasma-based heat and surface treatment manufacturing equipment for ferrous and non-ferrous metals industry in order to address the need for, and the lack of, such solutions in the market at the time. Plasmait developed proprietary plasma-based solutions, which became the technological leader in the field helping our customers in the metals processing industry to improve and optimise treating of materials in term of energy consumption, space requirements, use of chemicals and increase the quality of the products.

Plasmait has, through years, become a trusted and reliable supplier of solutions for metals processing industry to some of the leading metal processing companies in the world. Since its inception Plasmait has continuously expanded its geographical markets and improved its technology to become and remain the most technologically advanced provider or plasma-based solutions succeeding, in the process, in a whole range of market niches in non-ferrous as well as ferrous metals processing.

The company has developed a technological platform utilised in many different applications, like annealing, preprocessing before coating processes, like metallization, extrusion, taping and/or other.

Plasmait has sold many hundreds of its products to more than 30 customers worldwide, many of them being repeat business.

PLASMAIT TODAY

Today Plasmait is the undisputed technological leader for plasma-based heat and surface treatments manufacturing equipment for ferrous and non-ferrous metals industry.

Our solutions provide our customers with substantially lower overall production costs for their metals processing coupled with better operational control, higher quality and more durable end products and energy efficient operations. One other main benefit of our plasma-based solutions for metals processing is that the process is chemical and flux fee resulting in very environmentally friendly operations.

Customer satisfaction is paramount at Plasmait, and the fact that over 85% of our business is repeat business attests to our customers high satisfaction with our products and solutions.

We are proud that our products have been adopted by a large number of main metals processing clients throughout the world. Our customers provide us with a great base for future growth and development

Plasma technology can offer you a turn-key production lines, stand-alone machines or individual custom-made machines, designed for integration into your existing production lines.

Plasma treatment has proved its efficiency through:

lowest energy consumption per output amongst comparable industrial annealers (approx. 30% energy consumption reduction per kg of output in stainless steel applications),

smallest required power connection in class per kg of output (typically approx. 3 times smaller compared to conventional tube furnace),

lowest process gas consumption for continuous annealing in inert atmosphere (typically more than 30% reduction in gas consumption per kg of output),

lowest maintenance costs amongst equivalent industrial annealers,

high processing speeds allow in-line operation with drawing or plating and reduce the number of production lines per output and

small machine footprint per kg of output (PlasmaANNEALER would take approx. 1/3 of workshop space typically required by a conventional furnace).

Plasmait uses proprietary patented plasma technology for heat and surface treatment of various materials. Plasmait solutions have been utilized in continuous (wire, tube, strip) and batch production on a wide range of materials.

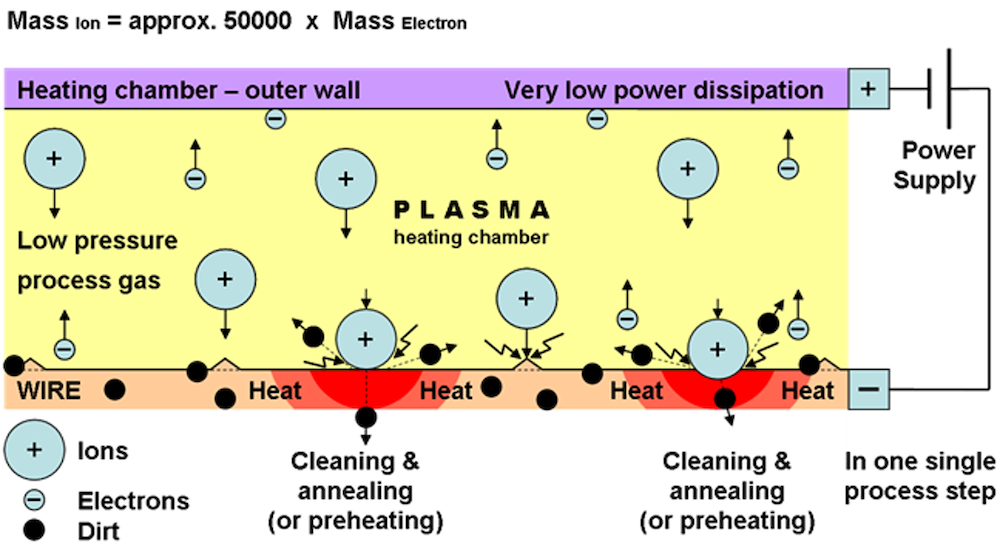

How plasma treatment works

Plasma heat treatment can be described as an ion bombardment on processed material surface. On impact with the material surface the ions release their energy to the material resulting in heating effect. Dirty deposits and oxides layers break under the impact of ion bombardment (micro sputtering) in the plasma chamber. Carbohydrate substances disintegrate at high temperature. Dirt, lubricants and oxides that are removed from the material surface in the plasma chamber are extracted through the exhaust pipe of the vacuum system.

Plasma treatment is generally not economical for removal of large quantity of contamination from the substrate surface. It is recommended that a suitable conventional precleaning is applied before plasma treatment in case of high surface contamination on the substrate material.

Plasma process can instigate chemical reaction on the wire surface, providing that the right choice of processing gas and process parameters is used. An example of such a surface treatment is dry (chemical-free) removal of surface oxides and lubricants. Plasma can be used as a dry alternative to acid pickling or electro-chemical polishing. Plasma treatment leaves the surface clean, dry and without catalysts for further oxidation. Plasma cleaned and deoxidised surface tends to oxidize at a slower rate than chemically cleaned surfaces with inadequate rinsing.

Unlike pickling or electro-chemical polishing plasma treatment does not lead to surface erosion or loss of base material. Plasma treatment does not damage the material surface unless extreme and unreasonably powerful plasma is applied to the processed material.

Chemically reactive plasmas are used for surface treatment applications. They instigate a specific chemical reaction of the material surface such as deoxidation, degreasing or surface activation/passivation.

Effects of plasma treatment on substrate material:

Accurate heating (e.g. annealing or stress relieving)

Dry surface cleaning (e.g. oxide removal, de-lubrication)

Increased micro-roughness and decreased macro-roughness

Change in surface energy (e.g. activation or passivation)

The magnitude of the above effects depends on the processed material and its surface condition as well as the type of plasma and its power.

Benefits of plasma treatment on substrate material:

Accurate and consistent heat treatment conditions

Rapid heat penetration into the body of the material

Consistent mechanical properties

Uniform grain size in horizontal and vertical direction

Bright and lean surface finish

Surface oxide removal without material erosion

Repeatable production conditions

Plasma machine operation and maintenance

The operation of plasma machinery is similar to the operation of a conventional continuous resistive. An operator of a conventional resistive annealing plant will also be able to operate a plasma treatment machine. Basic Training is provided as part of commissioning service, which will equip the operator for all aspects of machine operation and maintenance including:

Machine operation and safety

New application or product development

Machine maintenance

Plasmait machinery provides the operator with a safe production environment, incorporating the necessary safety features. The operator is given full control of the production process through:

User-friendly touch-screen HMI

Integrated production recipe database

In-line quality control

Production and machinery monitoring module

Consumption control module

Alarm database and spool labelling

Exportable production parameter and in-line measurement database

Plasma treatment is a contact-free process. Material does not touch the plasma chamber during heat treatment (as is the case in conventional furnace or resistive annealer). This prevents surface damage on the processed material and reduces physical wear of machine components and associated maintenance.

Efficient energy coupling makes plasma heat treatment one of the most efficient means of heating for most conduction materials. High heating efficiency is pronounced in high temperature ranges and high temperature applications where conventional means of heating show their weaknesses.

The consumption of purging gas is lower than the consumption of gas in conventional annealers. Process gas is fed to the plasma chamber at low-pressure making total gas consumption small when compared to the traditional annealer using inert atmosphere. Operation under the vacuum also minimizes the possibility of uncontrolled leakage and associated gas wastage.